Operating system: Windows, Android, macOS

Group of programs: Business automation

Goods storage management in warehouse

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download the program with interactive training

Interactive instructions for the program and for the demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

A large range of goods is stored in warehouses, so their correct placement in storage places greatly simplifies the entire work of warehouses. Depending on the volume of freight traffic, storage conditions, loading and unloading, storage and transportation of goods to the place of consumption, the warehouse is equipped with racks, pallets, weights and other measuring instruments, lifting and transporting devices, fire-fighting equipment.

The most important requirement that must be met by properly organized storage of goods in a warehouse is to ensure the qualitative and quantitative safety of stock. Warehouse workers must be well aware of the properties of the stored items, and the requirements of storage conditions, and master storage technology. Storage conditions include environmental conditions, that is, temperature, humidity, sunlight, etc. Storage technology includes schemes of placing goods in a warehouse, methods of stacking and processing them.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-04-26

Video of goods storage management in warehouse

This video can be viewed with subtitles in your own language.

The conditions and technology of storage of products mainly depend on their physical and chemical properties, therefore, they can be determined in relation not only to individual items, but also to whole commodity groups. The joint placement of items that are close in their physical and chemical properties, that is, stock of a uniform storage regime, ensures the correct commodity proximity, excluding the possibility of a harmful effect of goods on each other during joint storage.

Another condition for the possibility of shared storage is the interconnectedness of the range. Neighboring goods, released together, in a common lot, allows you to reduce the amount of movement in the warehouse. The functioning of the warehouse is accompanied by the costs of labor and technical resources. You can reduce these costs by dividing the entire assortment into groups that require a large number of transfers, and groups that are rarely accessed. Placing these groups of goods in different areas of the warehouse will minimize the number of movements in the warehouse.

Download demo version

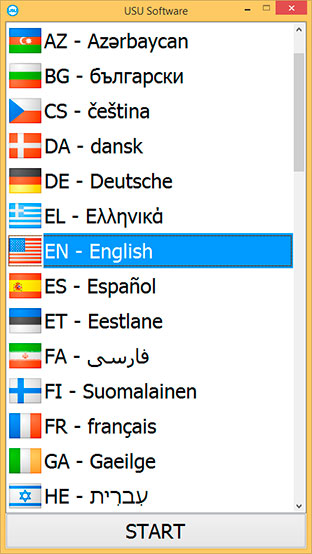

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

Instruction manual

Managing the storage of goods in a warehouse is essential to the retail business. In case of improper storage, finished items deteriorate, rot, all kinds of damage (fungi, corrosion and other negative phenomena), lose their original properties. If the management of the storage of goods in the warehouse is carried out unprofessionally, the enterprise will inevitably begin to lose profit. Analysis of the demand of stock at the initial stages can reduce the unreasonable risks of damage to inventory. Effective inventory planning and storage will provide consumers with the minimum they need and prevent unnecessary stockpiling of products in storage.

The organization of management of the storage of goods in the warehouse of a food-type enterprise involves the differentiation of item groups. They are divided into perishable and durable products. Perishable stocks require a canning and cold process. Suitable for long-term use do not require special storage conditions. The organization of management of the storage of items in a food warehouse requires the provision of changes that occur in the stocks as they are in storage. These processes include: physical, chemical, biochemical, biological, combined change in characteristics. Managing the processes of storing goods in the company's warehouses provides the availability of premises of warehousing and storage of stocks. By placing stocks in storage facilities, the entrepreneur assigns a permanent location to each type of product.

Order a goods storage management in warehouse

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Goods storage management in warehouse

This approach cuts down transportation costs and saves staff time. The arrival of stocks in storage becomes more mobile when using special warehouse equipment in the form of a barcode scanner and a special program. A variable method of warehousing and storage is also effective, in the case when goods and materials are well turned around, the vacated areas are filled with newly arrived stocks. This management requires certain techniques of the correct organization of the process. In reality, it is beneficial to use both tactics of placement: durable goods are in stable locations, while temporary goods are in variable storage locations. Management of the processes of storage of goods in the warehouses of an enterprise should provide some features: temperature regime, commodity proximity, production time, labor intensity. The purpose of the management is the effective placement of goods and materials, allowing to avoid damage, to carry out timely control, occupying the most profitable area.

Correct placement of racks and stacks, observance of norms for aisles will also significantly improve the process of placing and dispensing products and materials. Effective enterprise management, control and placement of goods and materials is possible due to the use of special warehouse programs. You can find a similar professional program on our website. What software features will you need for warehouse management? USU organizes all movements associated with products and materials: receipts, expenditures, movements, picking, inventory, write-off. The software perfectly interacts with the barcode scanner, the posting of items in this way significantly reduces the working time of storekeepers. The capabilities of the program cover relationships with suppliers, financial, warehouse, personnel records, analysis of the company's activities. You can contact us by phone number which you can find in the contacts, skype, by e-mail. We are ready to consider additional services for you. Make the organization of warehouse management automated, and make your business more efficient!