Operating system: Windows, Android, macOS

Group of programs: Business automation

Automated warehouse systems

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

During business hours we usually respond within 1 minute

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download the program with interactive training

Interactive instructions for the program and for the demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

A screenshot is a photo of the software running. From it you can immediately understand what a CRM system looks like. We have implemented a window interface with support for UX/UI design. This means that the user interface is based on years of user experience. Each action is located exactly where it is most convenient to perform it. Thanks to such a competent approach, your work productivity will be maximum. Click on the small image to open the screenshot in full size.

If you buy a USU CRM system with a configuration of at least “Standard”, you will have a choice of designs from more than fifty templates. Each user of the software will have the opportunity to choose the design of the program to suit their taste. Every day of work should bring joy!

Warehouses are important links in the technological process of industrial enterprises, and they serve as the foundation for wholesale and retail trade. In order to describe the most important characteristics of the warehouse itself, including the warehouse, one well-known logistics company has developed a warehouse classification system that most fully reflects the characteristics of the warehouse as a logistics and marketing unit. According to this classification of warehouses, all warehouse premises, regardless of their direct purpose, are divided into six categories. When determining the category of a warehouse, the following parameters are taken into account: geographical location, availability and condition of access roads to the warehouse complex, remoteness from highways, availability of a railway line, warehouse area, number of storeys, height of warehouse ceilings, availability of technical security equipment and many other parameters of the warehouse.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-11-05

Video of automated warehouse systems

At any enterprise, a part of the territory (areas) is necessarily allocated to the reception, unloading, storage, processing, loading and dispatch of goods. To perform such work, cargo platforms and platforms with access roads, specially equipped with technological means weighing and sorting points, etc. are required. Such objects of the enterprise's logistics infrastructure are warehouses. A warehouse is a complex of buildings, structures and devices designed for the acceptance, placement and storage of incoming goods, preparing them to consume and deliver to consumers, ensuring the safety of inventory, allowing the accumulation of necessary stocks. The main purpose of the warehouse is to concentrate stocks, store them, ensure uninterrupted and rhythmic supply of consumers in accordance with orders. In modern conditions, the attitude to warehousing is rapidly changing: it is no longer viewed simply as an isolated complex of intra-warehouse storage and handling operations but as an effective means of managing stocks and promoting material flows in the logistics supply chain of an enterprise. At the same time, warehouses are used exclusively in those cases when they are objectively necessary and really allow to reduce overall logistics costs or improve the quality of logistics services.

Download demo version

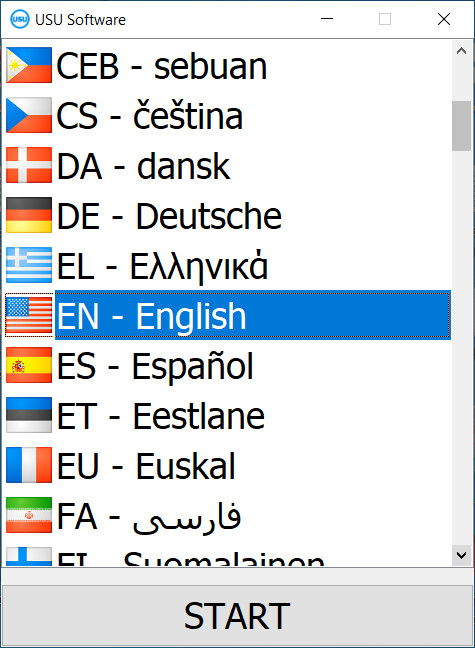

When starting the program, you can select the language.

You can download the demo version for free. And work in the program for two weeks. Some information has already been included there for clarity.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

Instruction manual

Layout task assumes the solution to the problem of rational organization of the internal system of the warehouse. The solution is based on the general principles of rational organization of the production process in time and space, but applied to warehouse systems. The goal is to maximize the use of the internal space of the warehouse (and not just its area). There are certain standard warehouses layout solutions of various purposes, capacity, and automating level. The system of the internal space of the warehouse is of great importance, that is, the order of distribution of volumes, zones and storage locations of individual objects within the warehouse, as well as tracing the routes of their delivery and removal, intra-warehouse movement and cargo handling. Materials of mass demand that enter the warehouse and are consumed in production in large quantities must be stored closer to the places of their receipt and issue. Materials received in containers should be stored in the same container, having appropriately equipped places of their storage, which should be taken into account in the layout of the warehouse. To maximize the use of the volume of storage systems in the warehouse, it is advisable to organize the movement of goods using overhead means of transport and loading and unloading (conveyors, beam cranes, bridge cranes, etc.) and to automate the warehouse system. It is advisable to organize the storage of goods in multi-tiered racks or in multi-row stacks, placing heavy loads at the bottom, and less heavy at the top. In this case, it is necessary to comply with the norms of the permissible load per unit area of the packaging of cargo, containers, racks, floors and interfloor floors.

Order an automated warehouse systems

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

Send details for the contract

We enter into an agreement with each client. The contract is your guarantee that you will receive exactly what you require. Therefore, first you need to send us the details of a legal entity or individual. This usually takes no more than 5 minutes

Make an advance payment

After sending you scanned copies of the contract and invoice for payment, an advance payment is required. Please note that before installing the CRM system, it is enough to pay not the full amount, but only a part. Various payment methods are supported. Approximately 15 minutes

The program will be installed

After this, a specific installation date and time will be agreed upon with you. This usually happens on the same or the next day after the paperwork is completed. Immediately after installing the CRM system, you can ask for training for your employee. If the program is purchased for 1 user, it will take no more than 1 hour

Enjoy the result

Enjoy the result endlessly :) What is especially pleasing is not only the quality with which the software has been developed to automate everyday work, but also the lack of dependency in the form of a monthly subscription fee. After all, you will only pay once for the program.

Buy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Automated warehouse systems

Automated warehouse systems are implemented in the USU software - under automated warehouse systems we mean their automation, which is the mentioned USU program. In automated systems, all accounting procedures and calculations are carried out automatically - based on the data available in them, which have stable internal connections with each other, therefore, a change in one value causes a chain reaction to change other indicators associated with the first value, either directly or indirectly. If an automated warehouse informing system works in production, all services interested in information about the availability and movement of inventories will receive updated data at the time of their update, since informing takes a split second for automated systems that are invisible to humans.

Production is interested in promptly informing about the current stocks in the warehouse, determining the period of uninterrupted operation with their available volume - the automated system offers all this at the above-mentioned speed, thereby accelerating the workflow in production, since the time of informing and, accordingly, taking the necessary solutions, is reduced many times, while the automated warehouse information system itself can offer the best solution in individual cases, which further increases its value. Its main task is to minimize all costs, regardless of the category - material, financial, time, live labor, which leads to a sufficiently high economic effect. The warehouse receives automated accounting, which provides the warehouse with automatic write-off of stocks transferred to production, and data updating without additional actions from the staff. If an automated warehouse informing system works in production, the company is always aware of which commodity items are available, in which warehouse they are located and in what quantity, how soon to expect new deliveries and from whom, how soon to make payments on obligations and to whom.