Operating system: Windows, Android, macOS

Group of programs: Business automation

Storage control in the warehouse

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

During business hours we usually respond within 1 minute

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download the program with interactive training

Interactive instructions for the program and for the demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

A screenshot is a photo of the software running. From it you can immediately understand what a CRM system looks like. We have implemented a window interface with support for UX/UI design. This means that the user interface is based on years of user experience. Each action is located exactly where it is most convenient to perform it. Thanks to such a competent approach, your work productivity will be maximum. Click on the small image to open the screenshot in full size.

If you buy a USU CRM system with a configuration of at least “Standard”, you will have a choice of designs from more than fifty templates. Each user of the software will have the opportunity to choose the design of the program to suit their taste. Every day of work should bring joy!

Today, automated control of storage in a warehouse is increasingly used. This allows managing the available raw materials and storage better and more efficiently. This type of control has many advantages. It is more reliable, productive, and allows taking into account all the smallest aspects of enterprise management. In addition, access to archival information, product accounting catalogs, and reference books that store additional information are opened. Also, this type of control permits a deep analytical analysis of the company's activities.

The USU Software presents to your attention several functional and practical ways of taking into account the industry specifics of an organization. The configuration of the program is quite simple and convenient. Raw materials and storage can be easily registered in the electronic database responsible for storage. In addition, the software makes it possible to create a special accounting and control card. The information is easily supplemented with various images that help to simplify the workflow. The system also allows importing and exporting large amounts of information without fear of missing something or losing any data.

The control of storage in the warehouse of the organization largely depends on the information part of the system, which automatically monitors the approaching deadlines for submitting reports. The control program prepares and forms various documentation, regulates the main production operations as a receipt, selection, and shipment of goods. Dispatchers will not need a lot of time and effort to parse and study automated control.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-11-05

Video of storage control in the warehouse

The USU Software is as simple and convenient as possible in terms of operation. It is aimed at ordinary warehouse employees. Its functionality does not include abstruse and unfamiliar phrases and terms, which gives it a significant advantage over other similar applications. Controlling storage in a warehouse also implies a developed communication system between subordinates, suppliers, and customers. Our software supports a number of information platforms required for information interaction like SMS, Viber, and E-mail. This will allow you to quickly exchange data on the availability of a particular product in the warehouse, promptly notify about the expiration of the storage time of certain products, as well as send a mailing, if necessary. Integration is also performed with most devices of a warehouse nature, which increases the productivity and quality of services, as well as staff mobility. In addition, you will no longer need to enter information on commodity items manually, which will save a lot of time.

The conditions of doing business today require the use of modern warehouse infrastructure, the active use of advanced technologies, applied computer programs, and automation systems for technological processes. The introduction of a quality control system for the services is in progress since this significantly affects the strategy of decisions and organization. movement of material flows.

The need for warehouses exists at all stages of the movement of material flow, from the source of raw materials to the final consumer of finished commodity products, which explains the wide variety of types of warehouses.

Download demo version

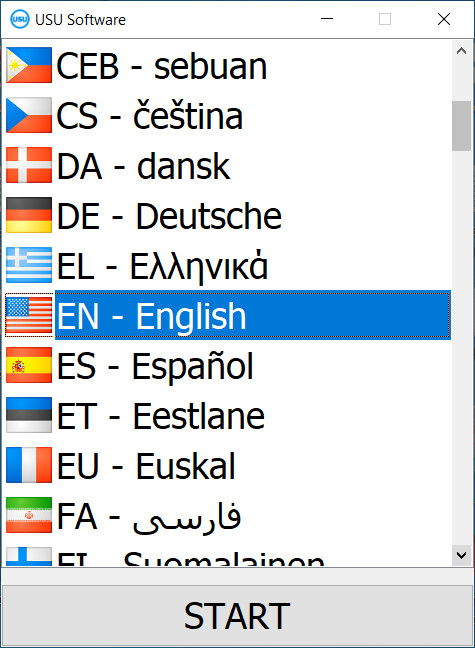

When starting the program, you can select the language.

You can download the demo version for free. And work in the program for two weeks. Some information has already been included there for clarity.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

Instruction manual

The number of possible options for the implementation of the components of the warehouse system can be significant, and their combination in various combinations further increases the multivariance of the system. The concept of designing a warehouse facility requires serious planning prior to the technical implementation or organizational measures to create a warehouse.

In the process of storage control in a warehouse, preparing them for release, and performing other warehouse operations, commodity losses occur. If the warehouses' operations of acceptance, storage, and release of goods are tracked using our USU Software system for warehouse control, their losses are minimized.

Failure to maintain control of the warehouse and the goods stored on it may indicate the presence of problems in the system of goods distribution, which requires an urgent review of the entire warehouse system and the introduction of effective automated programs.

Order a storage control in the warehouse

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

Send details for the contract

We enter into an agreement with each client. The contract is your guarantee that you will receive exactly what you require. Therefore, first you need to send us the details of a legal entity or individual. This usually takes no more than 5 minutes

Make an advance payment

After sending you scanned copies of the contract and invoice for payment, an advance payment is required. Please note that before installing the CRM system, it is enough to pay not the full amount, but only a part. Various payment methods are supported. Approximately 15 minutes

The program will be installed

After this, a specific installation date and time will be agreed upon with you. This usually happens on the same or the next day after the paperwork is completed. Immediately after installing the CRM system, you can ask for training for your employee. If the program is purchased for 1 user, it will take no more than 1 hour

Enjoy the result

Enjoy the result endlessly :) What is especially pleasing is not only the quality with which the software has been developed to automate everyday work, but also the lack of dependency in the form of a monthly subscription fee. After all, you will only pay once for the program.

Buy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Storage control in the warehouse

The rational organization of the warehouse process should help to reduce the time spent on handling vehicles and serving consumers, increasing labor productivity and reducing the costs of warehousing and storing materials, as well as eliminating unnecessary overloads and movement of goods.

Automated control of storage in the organization's warehouse simplifies the process of conducting scheduled inventory. The application independently verifies the data on the stock of this or that raw material, noting financially vulnerable and, conversely, stable positions. As a result of this approach, the organization will be able to optimize and establish a commodity circulation in which all steps are controlled by a computer. By the way, planning will also be handled by software. It will be able to predict the development of the company in the near future, using the analytical analysis of available data.

Automated control ensures an increase in the quality of warehouse storage. Automation allows optimizing the work process as a whole, as well as increasing the efficiency and quality of staff work.