Operating system: Windows, Android, macOS

Group of programs: Business automation

Production process control

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

During business hours we usually respond within 1 minute

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

A screenshot is a photo of the software running. From it you can immediately understand what a CRM system looks like. We have implemented a window interface with support for UX/UI design. This means that the user interface is based on years of user experience. Each action is located exactly where it is most convenient to perform it. Thanks to such a competent approach, your work productivity will be maximum. Click on the small image to open the screenshot in full size.

If you buy a USU CRM system with a configuration of at least “Standard”, you will have a choice of designs from more than fifty templates. Each user of the software will have the opportunity to choose the design of the program to suit their taste. Every day of work should bring joy!

The control of the production process consists of three main stages, which, in turn, are divided into shorter stages and operations. The first point in the control of the production process is the control over the production raw materials, starting with the selection of the supplier and quality control during the purchase. The second stage is the actual control over the production process with its operational division into shorter working sections. The third stage belongs to the control over the quality of finished products. Production consists of several components - these are the main and auxiliary production processes, as well as the process of servicing the processes themselves in production.

Operational control of the production process consists in control over technological operations, including monitoring them in case of surgical intervention in order to comply with the norms and standards of production established in the industry, full compliance of the manufactured products with the requirements for it. The enterprise includes in the control of the production process control over the state of the environment and equipment involved in production.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-11-22

Video of production process control

Regular monitoring of the production process at the enterprise has preventive goals to prevent emergencies that can occur in production, and ensures the quality of the products at the proper level. Effective control of production processes at the enterprise is carried out by the software "Universal Accounting System" in the current time mode, i.e. any changes in the production process will be immediately registered and communicated to the responsible persons with the time spent on the entire informing process no more than a second. In addition to production control, the enterprise, in the same current mode, carries out such types of control as inspection and operational control; in aggregate, they constitute managerial control of production processes.

Management control of production processes consists, first of all, in planning and organizing work to control the operational identification of discrepancies between the results obtained in production and those established in the industry where the enterprise operates, standards and rules. The next point of the control program is the analysis of the results obtained by the production and the identified discrepancies so that the company can quickly determine their causes and make the necessary adjustments to the production process. Thirdly, there must be effective communication between persons exercising control over the production process, including all its constituent stages, in order to timely perform the required correction of the production process. The fourth function of management control of production processes at the enterprise is the direct regulation of the production process.

Download demo version

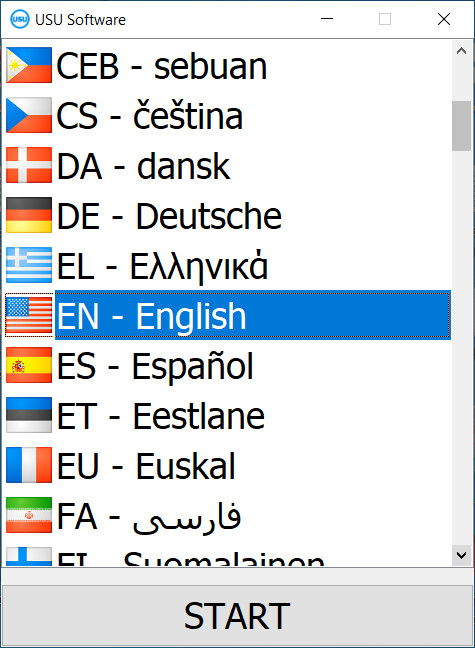

When starting the program, you can select the language.

You can download the demo version for free. And work in the program for two weeks. Some information has already been included there for clarity.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

All these stages of control are successfully carried out by the above-mentioned USU program, providing the enterprise with everything necessary to conduct effective production control, providing, among other things, an internal notification system for sending prompt notifications to persons interested in control. The format of notifications is pop-up windows in the corner of the screen, when you click on it, the corresponding document opens with the subject of discussion and approval in the forum mode.

In addition, the company actively uses the built-in database, which contains complete information on industry regulations and standards, requirements for production processes and recommendations for control. This regulatory framework is regularly updated to ensure that the values presented are always up to date, and includes information on the accounting and calculation methods used in the industry. Due to the availability of such information, the analysis of production indicators is also carried out in the current time - for this, the program provides a whole section called Reports, where you can get information about deviations from the officially established norms and, if any, assess the depth of the discrepancy and identify the influencing factors that caused deviation from the norm. In addition to the Reports section, two more sections are presented - these are Modules and References.

Order a production process control

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

Send details for the contract

We enter into an agreement with each client. The contract is your guarantee that you will receive exactly what you require. Therefore, first you need to send us the details of a legal entity or individual. This usually takes no more than 5 minutes

Make an advance payment

After sending you scanned copies of the contract and invoice for payment, an advance payment is required. Please note that before installing the CRM system, it is enough to pay not the full amount, but only a part. Various payment methods are supported. Approximately 15 minutes

The program will be installed

After this, a specific installation date and time will be agreed upon with you. This usually happens on the same or the next day after the paperwork is completed. Immediately after installing the CRM system, you can ask for training for your employee. If the program is purchased for 1 user, it will take no more than 1 hour

Enjoy the result

Enjoy the result endlessly :) What is especially pleasing is not only the quality with which the software has been developed to automate everyday work, but also the lack of dependency in the form of a monthly subscription fee. After all, you will only pay once for the program.

Buy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Production process control

In the Modules, direct control over the production process is carried out, operating indications are noted, indicators are calculated. It should be noted that the accounting procedures are organized in the program without the participation of employees of the enterprise, i.e. are carried out automatically, the duties of employees include only the input of current and primary readings into the automated system. Therefore, Modules are a user's workplace, other sections are not available to them.

Reference books are a section where the regulation of production processes, accounting and accounting procedures is determined, the calculation of production operations is configured, which allows automatic calculations, and also contains the regulatory and methodological base on the basis of which the calculation is organized. All calculations guarantee high accuracy and error-free calculation algorithm, there is no subjective factor.