Operating system: Windows, Android, macOS

Group of programs: Business automation

Organization quality control of production

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

During business hours we usually respond within 1 minute

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

A screenshot is a photo of the software running. From it you can immediately understand what a CRM system looks like. We have implemented a window interface with support for UX/UI design. This means that the user interface is based on years of user experience. Each action is located exactly where it is most convenient to perform it. Thanks to such a competent approach, your work productivity will be maximum. Click on the small image to open the screenshot in full size.

If you buy a USU CRM system with a configuration of at least “Standard”, you will have a choice of designs from more than fifty templates. Each user of the software will have the opportunity to choose the design of the program to suit their taste. Every day of work should bring joy!

Quality control in production is of no small importance, since the quality of manufactured products depends on it - one of the main factors for its successful sale. To organize effective quality control in production, it is imperative, at least, to ensure quality control at the production stage, which is responsible for the assembly of products, when any flaw in the workpieces, components, etc. becomes obvious.

The production of goods, as a rule, consists of several stages, and if each production stage is under strict control, then this will not only be a big step towards high quality products, but will reduce the cost of its implementation, since material and labor resources will be strictly regulated by quantity and time. Automation of quality control in production allows you to organize control over each production stage or strengthen it to a significant extent, if it is already installed.

Thanks to automated control over production, costs in general and / or for a specific production stage are reduced, the time of the personnel exercising this control is freed up, the time for solving current issues is reduced, since automation will be related not only to quality issues, but also to optimize internal activities enterprises, which, of course, affects the state of production stages - the productivity of the enterprise increases, its profitability increases.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-11-22

Video of organization quality control of production

Automation of quality control in production is carried out by Universal Accounting System, offering universal software developed by it for production, the scale and scope of which are important at the stage of setting up the program, but do not in any way affect the operation of the application.

The quality control automation program in production is distinguished by a simple interface, convenient navigation and an understandable menu structure, so employees who have received the right to work in it do not have to worry about their skills and knowledge of the computer - they will successfully cope with their duties, because it is really easy, so more, they are only charged with inputting primary information at different stages of production and control over the current situation.

The installation of the program for automation of quality control in production is carried out by the employees of the USU, when buying one license, the customer receives a short training course for one employee, although the software functionality can be mastered independently. The quality control program menu consists of three sections. These are the Modules, References and Reports blocks.

Download demo version

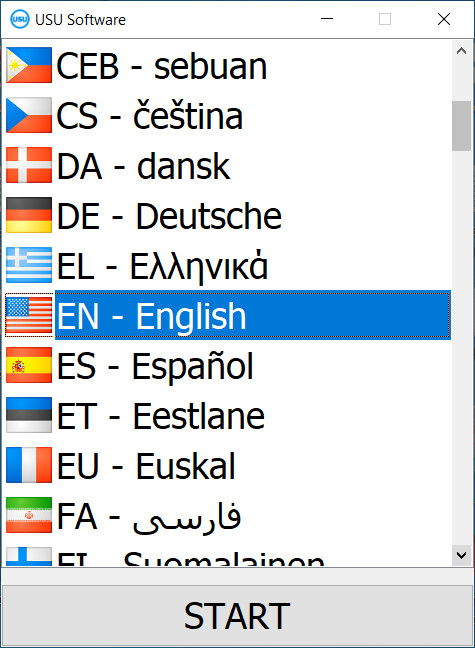

When starting the program, you can select the language.

You can download the demo version for free. And work in the program for two weeks. Some information has already been included there for clarity.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

To set up processes, procedures and calculations in the automation of quality control in production, first fill out the References block, placing in it information about production and the enterprise. For example, there are four tabs in the block - Money, Organization, Product, Services. It is immediately clear what kind of information should be present in them.

In the Money folder, they make a list of currencies that are involved in settlements with customers and suppliers, list expense items according to which the company sends money, and sources of income, and also indicate payment methods through which products and / or services can be paid, and types of bonuses. which can be used as payment.

Further, the quality control program proposes to fill out the heading Organization - indicate the production "real estate", including branches and warehouses, provide a list of employees and their "affiliated" persons, including their details, and indicate those sources of information with which the company cooperates in promoting products and services.

Order an organization quality control of production

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

Send details for the contract

We enter into an agreement with each client. The contract is your guarantee that you will receive exactly what you require. Therefore, first you need to send us the details of a legal entity or individual. This usually takes no more than 5 minutes

Make an advance payment

After sending you scanned copies of the contract and invoice for payment, an advance payment is required. Please note that before installing the CRM system, it is enough to pay not the full amount, but only a part. Various payment methods are supported. Approximately 15 minutes

The program will be installed

After this, a specific installation date and time will be agreed upon with you. This usually happens on the same or the next day after the paperwork is completed. Immediately after installing the CRM system, you can ask for training for your employee. If the program is purchased for 1 user, it will take no more than 1 hour

Enjoy the result

Enjoy the result endlessly :) What is especially pleasing is not only the quality with which the software has been developed to automate everyday work, but also the lack of dependency in the form of a monthly subscription fee. After all, you will only pay once for the program.

Buy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Organization quality control of production

In the heading Goods, the automation of quality control in production places the nomenclature and the list of categories, according to which the assortment of materials and goods is divided into groups for the quick search for the desired products, here is also a complete set of price lists of the enterprise, and there can be many time, regular customers can receive "dividends" in the form of an individual price list.

Similarly, under the heading Services, a program for automating quality control in production is presented, it presents a catalog of services and a list of categories into which services / works are divided. The service catalog lists the stages of its formation and the time planned for the implementation of each stage, presents the pricing for each stage and provides a calculation of the materials involved in each production stage. In production, a margin is used, so they should also be indicated - for what and in what volume.

It is in the References section that the individual characteristics of production are taken into account during its automation, therefore the software works for any enterprise - large or small.

In addition to Directories, the software for automating quality control in production has a Modules block, where employees of the enterprise work, stores current working information on customers, orders, a warehouse, and a Reports block, where performance indicators are analyzed, the quality of each production stage is assessed.