Operating system: Windows, Android, macOS

Group of programs: Business automation

Inventory control in manufacturing

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download the program with interactive training

Interactive instructions for the program and for the demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

Warehouse inventory control in production is the basis of its well-coordinated and efficient work. Having no control over manufacturing, documentary or employees’ work can lead to unacceptable mistakes and losses. The inventory control in manufacturing of the organization is very important, since it is the order in the organization of the warehouse that leads to order in accounting. Every part is closely connected with others and without regulations that unite everything there is no chance to make your enterprise work properly and no chance to be the best on the market. Many methods have been invented for warehouse balances accounting, both paper ones, like books and material control logs, and modern, highly professional automatic programs, which, depending on their pumping, can automate not only inventory accounting, but almost every manufacturing process. While the progress is growing with frantic pace we are used to use old methods that just can’t be improved. Having papers and piles of documents everywhere, spending hours trying to find the one which was urgent to find some hours ago. That doesn’t bring pleasure to people who work as well as doesn’t add any efficiency to the manufacturing. It may cause bigger and bigger amount of problems that you don’t have time to solve. However, the century of technologies bring us useful inventions like programs to control and simplify manufacturing and work in general. Our task is just get used to it and start using it in order to reach new heights.

Who is the developer?

2024-04-20

Video of inventory control in manufacturing

This video can be viewed with subtitles in your own language.

One of such popular programs, with a wide selection of tools to control inventory, is a unique development from USU specialists Universal Accounting System. The advantages of this system far exceed other controlling programs. In order to get the fullest information or to download, contact us on the official website and our specialists will answer all your questions and help to make right decision.

Download demo version

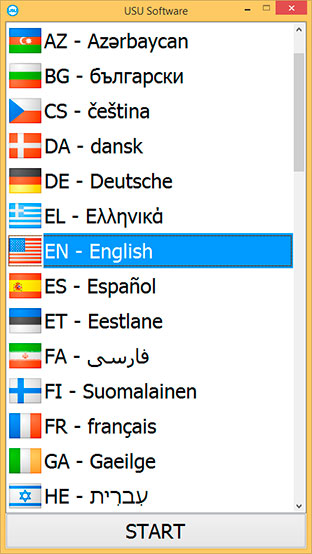

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

Instruction manual

This product is designed to make life easier for managers and entrepreneurs, as it covers absolutely every stage of manufacturing, freeing the hands of employees and minimizing the time and probably inventory wasted before. The program isn’t difficult to use and you don’t have to have special, modern computers to make it work. Even if your staff had no prior experience in maintaining automated warehouse inventory control in production, work in our computer installation will not cause difficulties, since it is designed as simply and accessible as possible. We also thought about good feeling and emotions working with the software, so even design can be changed according to your preference. After you access the system with the password and login, which are individually given to each employee, you see the working screen of the system divided into three sections, each of which has its own purpose. In comparison with other programs to control inventory, the main window as the system itself is not overloaded with sections, icons or functions that you even don’t understand in what purposes to use. The most frequently used section Modules is a place in the workspace, which consists of special tables, in which the storekeeper or accountant enters the most important information about internal reception, inventory, consumption and movement of balances. The system is smart, so the given to the computer information goes to other places where it has to be. Each stage is detailed and documented in the system and this greatly speeds up the work of controlling storage locations. To begin with, when using our computer software, the number of created warehouses is not limited in any way. Data is saved for unlimited time either. Considering the versatility of each production, this is at least necessary, because consumable inventory, raw materials, finished products and factory defects must be taken into account separately. Therefore, more often than not, in manufacturing, a separate accounting is kept for the workshop, which mainly contains raw materials and inventory used in the manufacturing of finished products, and a separate warehouse for finished products. You can form your groups, make your own filters to make working and manufacturing control and accounting convenient. Accounting can be carried out in any conventional units of measurement, which greatly facilitates the accounting of balances in the production warehouse. There is a very useful option in the References section for automated production control, the ability to create a so-called kit for the finished product, which will take into account the raw materials used. This important function makes it possible to carry out, simultaneously with the receipt of finished products from the workshop to the storage location, the write-off of materials from the workshop warehouse. The system is multi-users and multi-functional, so the saving time you will be able to feel from the first day of downloading and installing. In addition, in the References section, which is useful for the company's capabilities, you can register legal information about the company, as well as indicate the minimum for the most popular consumable items from raw materials. With the range of such functions, you won’t have to worry about unpredictably appearing nuances that can stop or delay manufacturing. Having taken this step, you no longer run the risk of getting into unpleasant situations with a sudden end of important materials, since the Universal System will automatically track them and notify the shop staff that their number is already close to a minimum.

Order an inventory control in manufacturing

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!