Operating system: Windows, Android, macOS

Group of programs: Business automation

Consideration warehouse operation

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download the program with interactive training

Interactive instructions for the program and for the demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

Consideration of the warehouse operation involves solving the problem of rational consideration of the warehouse operation in time and space as part of the production operation. In this case, the goal is pursued: as far as possible and wherever possible, to organize the performance of warehouse operation by flow methods. There are certain standard solutions of warehouses with different specializations, different types of operation and levels of automation. When organizing warehouse operation, it is necessary to achieve: rational layout with the allocation of working areas, which contributes to the rational consideration of the operation of handling goods and reducing costs; efficient use of space when arranging equipment, which allows you to increase the capacity of the warehouse; widespread use of universal equipment that performs various warehouse operations, which gives a significant reduction in the fleet of lifting and transport devices: minimization of routes of intra-warehouse movement of goods, which allows increasing the throughput of the warehouse and reducing operating costs; optimization of shipments and the use of centralized delivery, which can significantly reduce transport costs; maximum use of the capabilities of the information system, which significantly reduces the time and costs associated with paperwork and information exchange.

Who is the developer?

2024-04-18

Video of consideration warehouse operation

This video can be viewed with subtitles in your own language.

Comprehensive mechanization and automation of labor-intensive loading and unloading and other cargo handling operations is the most important factor in increasing labor productivity and reducing the cost of warehouse operations. The most numerous and varied in composition are material warehouses. Their number, specialization and size are determined by the nomenclature and volume of goods consumed by the main and auxiliary workshops serving the farms of a particular enterprise. Material warehouses are subdivided into warehouses of ferrous and non-ferrous metals, fuel, chemicals, etc.

Download demo version

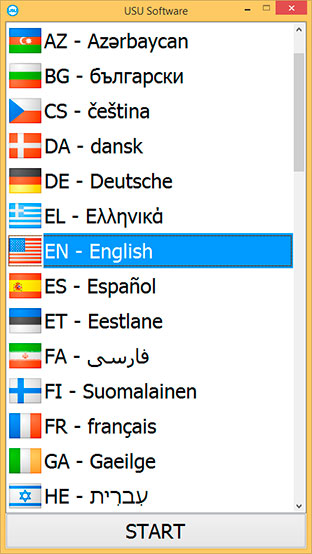

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

Instruction manual

Purchased products from external suppliers arrive at the material warehouses of the enterprise. The main task of warehouses at the enterprise is the complete and uninterrupted provision of workshops, sections and workplaces with all types of goods and semi-finished products in strict accordance with their needs. This task can be solved only with accurate planning of production needs of resources, effective management of supply at the enterprise and the correct consideration of supply of shops with warehouses. This is achieved by integrating local warehouse information systems into the enterprise resource planning system, establishing electronic data exchange over telecommunication networks with external suppliers of items, as well as developing an end-to-end technological operation and a schedule in the supply chain ‘external supplier materials – factory warehouse - workshop warehouse - production area of the workshop – workplace’.

Order a consideration warehouse operation

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Consideration warehouse operation

Today, every enterprise needs to automate warehouse consideration in order to comply with quality standards in the conditions of high dynamics of modern business. In the operation of managing a warehouse, you have to deal with various calculations, on the basis of which the execution of tasks such as procurement planning, replenishment of goods, determining a product range to sale, pricing, development of bonus systems and discounts of customers and many others is built. The ultimate accuracy of considerations, which directly affects the correctness of management decisions, can be ensured in the case of using computer programs and automation technologies.

On the market of computer applications, you can find many consideration systems, however, they do not fully correspond to the specifics of the work of warehouses, so their application will not be sufficiently effective. The USU Software was created by our developers specifically to fully control and competently develop the trade and warehouse; therefore work in it is convenient, efficient and highly effective. Our program provides its users with all the tools necessary to conduct and optimize warehouse operations, as well as to thoroughly study the associated operation. The software developed by us is a modern multifunctional system, which is aimed at the comprehensive improvement of both production and operational activities of the company. In the program, users can deal not only with inventory control, but also with document circulation, product sales, development of relations with contractors, financial monitoring and many other tasks.

Thus, all areas of activity will be organized in accordance with unified rules for the successful and rapid achievement of goals. Users will have at their disposal a visual base of recording various movements of inventories in the warehouse: receipt, transfer, write-off and sale. Since in the conduct of warehouse consideration, not only accuracy is important, but also the promptness of updating information, after each change in the structure of inventory items, the program will automatically recalculate the remains of crudes and products. Thus, you will always work with only up-to-date information for procurement planning. The tools of our program allow you to build an effective procurement operation at the enterprise, in which responsible specialists can draw up procurement schedules from suppliers, track the availability of stocks in the required volumes, assess the rationality of resource use and ensure the specified sales volumes. Warehouse analytics will not take a lot of working time: to assess the availability of a company with goods, you can use the export of a report on goods that are running out.