Operating system: Windows, Android, macOS

Group of programs: Business automation

Program for production optimization

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

The production optimization program ensures that you work with the best results with the existing production capacity, labor resources, stocks of raw materials and materials, production conditions and requirements for finished products. The production program is the fulfillment of the production plan, the sale of finished products for the annual period at the current state of production. The production program is divided by quarters, by months, within the structural unit, work on its implementation can be distributed over shorter periods.

It is based on the task to maximize the satisfaction of the customer's needs in purchasing high quality goods that the company produces at the lowest cost. This means that the optimization of the production program of the enterprise should provide for a systematic reduction of non-productive costs, which include downtime, rejects, transportation costs, relocation of warehouse stocks and, consequently, overproduction itself and excess of the number of work operations. To get a real optimization of the program, you should consider the continuity of the process and the level of customer demand.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-04-27

Video of program for production optimization

This video can be viewed with subtitles in your own language.

There are two options for optimization: the production program must provide either the best result in making a profit with the potential of the enterprise, or a given volume of production at the lowest cost. The production optimization program is of great importance in the production, economic activities of the enterprise and is constantly monitored by its management.

Methods for optimizing the production program differ in types, therefore, their choice is carried out according to the goals and stages of development and / or correction of the production program. First of all, the company must determine the structure of products and the volume of output of each of its names. Then the analysis of different variants of this structure according to the demand for products is carried out, at the same time the labor intensity of work is assessed at the current production productivity, the qualifications of labor personnel. A decision can be made to introduce new production equipment and, accordingly, the needs of the enterprise in the volume of raw materials, consumables, personnel, and transport services will change.

Download demo version

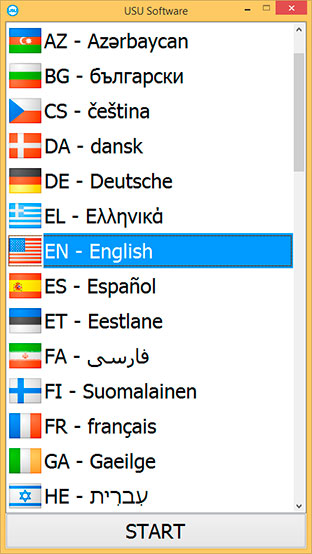

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

For the formation of the production program, the choice of the method for its optimization, the enterprise must make a decision on automation, since it is this option that will make it possible to draw up the production task as competently as possible, find the optimal ratio of the nomenclature and identify non-productive costs or costs. When installing the Universal Accounting System software for industrial enterprises, which is installed remotely on the customer's computers by the USU employees themselves, the production program will be drawn up taking into account real, objective indicators, which will already allow it to be effective and realistic.

It should be mentioned that only USU products in the proposed price range have the function of generating statistical and analytical reports, which are issued regularly after the reporting period, the duration of which is determined by the company. This is a powerful informational tool for the management staff, since it allows making not only correct strategic decisions, but also very far-sighted ones both in the adoption of the production program and in its optimization.

Order a program for production optimization

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Program for production optimization

The software configuration for optimizing the production program provides the enterprise with a complete alignment of all work results - production resources, personnel productivity, the range of products and the number of the entire assortment, customer needs in each item, profit from each unit of the product, etc. In addition to such systematized and structured data, the company will receive real-time control over the movement of funds, which will allow it to quickly identify inappropriate expenses, monitor the dynamics of changes in expense items over time, comparing the planned costs with those that actually happened in each period.

In a similar way, control over raw material stocks will be established, automated warehouse accounting will automatically write off the volume of raw materials transferred to production. Any movement of stocks is documented by the software configuration for optimization by means of its own invoices, which are saved forever in the accounting system.

For effective inventory accounting in the optimization software configuration, a base of raw materials, consumables, finished products has been formed - a nomenclature, where each name has its own distinctive features, such as a barcode, factory article, etc., its quantity is indicated with a layout for all warehouses, departments. The corresponding report in the software configuration for optimization will show the discrepancy in the planned amount of raw materials and the actually consumed, identifying its causes and, thereby, indicating the source of costs.