Operating system: Windows, Android, macOS

Group of programs: Business automation

Management of industrial production

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

Industrial production management today cannot be manual, since global and regional processes in any industry require a prompt response to any change in the environment. The software "Universal Accounting System" makes it possible to organize the management of industrial production in the current time, which means instantaneous reflection of any change in industrial production on the indicator of industrial activity.

Industrial production is distinguished by the scale of activity and in the absence of automation it takes a lot of time and effort to inform about its results, changes in production rates, reduced profits, etc. Therefore, production management in industry is considered effective if only this management is the object of the automation program.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-04-25

Video of management of industrial production

This video can be viewed with subtitles in your own language.

Industry is made up of different industries - large and small, private and public, the software configuration for production management in industry is suitable for any of them, therefore it is called universal. Each industrial production has its own individual characteristics, regardless of the scale of activity and form of ownership.

These features of production, as well as features in the management of such production, will necessarily be reflected in the software configuration for production management in industry, despite its versatility, which means applicability in any production with its personal control. The possibilities of software configuration for production management in industry also provide for the effective management of the industry itself, in this case, individual industrial production acts as users, providing the industry not only with their current data, but also the results of regular analysis provided in the framework of industrial production management, according to which it is possible to objectively evaluate industrial results.

Download demo version

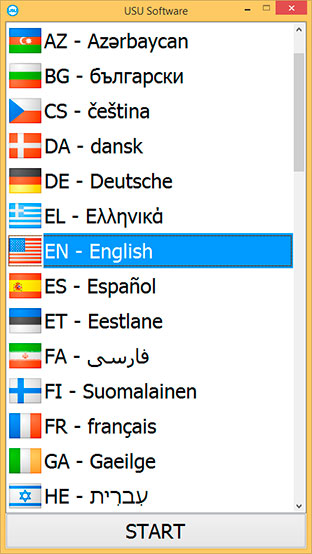

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

The software configuration for industrial control consists of three structural blocks that take an active part in the management of the industry and perform their functions in the organization of such control - these are Modules, References and Reports. The first and third of them are of more informational value - in the Reference books the information and reference department, in the Reports of the information and assessment department. In the second block, Modules, the operational management of all operational activities of the industry, including industrial processes, is carried out, the data on which are fed into the software configuration for industrial control from their performers themselves - workers from production sites who are involved in work in the system to manage the current state of the industrial process ...

Their responsibilities include the prompt registration of each such change, carried out by entering information about this change into an automated control system. The involvement of lower-level personnel gives the industry more operational opportunities, since information about the current state of the industrial process comes directly from its participants, which makes this information as fast and reliable as possible. The participation of workers themselves in the industrial management program is ensured by its simple interface and easy navigation, which makes this program accessible to everyone, regardless of the availability of user experience and skills, even in their complete absence.

Order a management of industrial production

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Management of industrial production

In order to preserve the confidentiality of industrial information in full, separate access to it is used by assigning individual logins and passwords to them to each employee admitted to the management program. This allows you to enter the personalization of data stored in the system under the username in order to control its quality and the timing of the employee's duties, since in the industrial management program, in addition to data registration, there is also a record of the time of entry and entry of the record.

Taking into account the fact that the industrial management program automatically calculates piece-rate wages for the personnel working in it based on the registered work, the interest of users in the timely data entry and reporting on completed tasks increases for the prompt transfer of information to the next level. At the same time, it disciplines staff, which in turn increases productivity.

One of the main objectives of the management program is to improve the efficiency of industrial activities, as mentioned above. In addition to the growth of personnel productivity, there is an increase in the speed of processes due to the prompt coordination of deviations arising in the work, which also only has a beneficial effect on the state of industrial production.

The industrial control program does not have a subscription fee, is easily integrated with modern equipment and, thereby, improves the quality of industrial operations, mutually expanding the functionality.