Operating system: Windows, Android, macOS

Group of programs: Business automation

Calculation of costs for production

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

Calculation of production costs in the "Universal Accounting System" software makes it possible to correctly estimate the cost of a specific product and find a way to reduce it, since the lower the cost, the higher the profit of the enterprise and the rate of profitability of production. Under the production costs, the current costs are taken, which ensure uninterrupted operation in the reporting period, taking into account the required amount of resources. Due to the correct calculation of production costs, the company increases the turnover of assets and does not generate more costs than is required to complete the planned volume of work.

The calculation of the reduction in production costs allows you to increase its volume while maintaining the same amount of production resources, the very reduction in specific production costs is due either to a decrease in material costs, or to an increase in labor productivity. To reduce material costs, there are several specific ways using which you can achieve tangible results. For example, this is the use of better quality raw materials, however, such raw materials will cost more, but its consumption will also be less due to a decrease in material rejects. Or, conversely, an increase in the technical level of production, which leads to a decrease in time costs, an increase in product quality, a decrease in the percentage of specific defects in production, etc. The second option to reduce production costs is labor productivity, which increases by attracting more qualified personnel to production, staff motivation, etc.

Who is the developer?

2024-04-18

Video of calculation of costs for production

This video can be viewed with subtitles in your own language.

There are several options for calculating the reduction in production costs, including those indicated above, for each there is a specific formula. A preliminary calculation of the costs of manufacturing a specific type of product allows us to assess the capabilities of an enterprise for its production, to weigh all the pros and cons in accordance with current costs and the level of customer demand for such products. Methods for calculating production costs in the software configuration for calculating the reduction of specific costs are provided in two options - for economic cost elements, which, in fact, represent the cost of all products, and for cost items per unit of production.

A description of each method is given in the industry methodological base, which contains specific recommendations for keeping records and organizing settlements for all types of activities of an enterprise operating in this industry. Such a methodological base is built into the software configuration for calculating the reduction of specific costs and contains all the norms and standards for performing production operations, rates of resource use, industry documentation with calculation formulas, including for cost reduction.

Download demo version

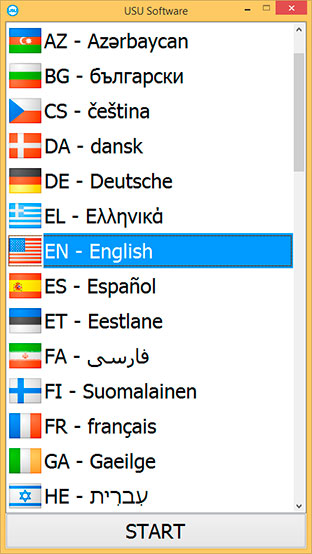

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

Production costs, the calculation formula for which is present in the aforementioned base, participate in the pricing process, which makes it possible to calculate the most optimal price for the successful sale of a particular product, which, in turn, increases the chances of an enterprise for its competitiveness and eliminates the likelihood of becoming a loss-making enterprise.

The software configuration for calculating the reduction of specific costs has a simple interface and convenient navigation, an understandable presentation of information, and all this in combination allows attracting production workers, as a rule, who do not have computer skills, to work in it, but in this case they quickly master the program for calculations and promptly provide the enterprise with specific production information. This is important for an enterprise because it allows you to quickly assess the current state of the production process and quickly respond to its changes if they occur.

Order a calculation of costs for production

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Calculation of costs for production

The task of users is the timely registration of working data, the rest of the work is performed by the program for calculations independently, preventing personnel from accounting and calculations, which immediately increases their efficiency - by reducing labor costs and speeding up all processes. Accordingly, labor productivity increases - the staff begins to work in a regulated manner, in terms of the amount of work and according to the deadlines for completing tasks, since the program for calculations automatically calculates piece-rate wages of personnel based on information about specific jobs that are registered in it for the reporting period.

This disciplines the employees, since it is impossible to agree with the program for settlements, therefore the only way out is to timely fulfill the duties, since the time of entering the information is noted in the system. And the management controls this process - the quality and terms of execution, having a convenient audit function, whose responsibilities include allocating the required volume of user data, by which you can quickly determine the reliability of his data and evaluate the work performed. This feature speeds up the process of monitoring electronic user logs, which are purely personal and open only to management, not including the owner. Personalization of information excludes the possibility of postscripts, inaccuracies.