Operating system: Windows, Android, macOS

Group of programs: Business automation

Automation of production control

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

Control of production of products implies the organization of special measures to control production, its individual stages, their compliance with standards and norms of performance, compliance with the equivalence of planned production indicators and actual ones, which is characterized by stability in production in terms of stocks and costs of products, and this is also an indicator of production quality products. In addition to production, the product itself is also under control, since its final condition, which meets the requirements, is also an indicator of the quality of the production itself.

The organization of control over the production of products includes in the field of its activities all structural parts of production, including production stocks, starting from the moment they enter the warehouse of the enterprise, since the quality of raw materials directly affects the state of the finished product, even after going through numerous production processes.

Who is the developer?

2024-04-20

Video of automation of production control

This video can be viewed with subtitles in your own language.

Therefore, food production control primarily relies on raw materials, examining their quality from the moment these raw materials were still the property of the supplier. Food products are susceptible to storage conditions, therefore their location in the warehouse is subject to strict control, and the warehouse itself is subject to control over warehouse equipment. Food products and food raw materials are examined in production laboratories to make sure that their original properties are preserved; for this, the organization of regular analysis of samples for biochemical, physical and taste qualities is introduced.

The analysis is a logical continuation of control, therefore, control of production of products is accompanied in the software "Universal Accounting System" by the organization of analytical reporting, which presents the dynamics of changes in the quality of products, including food, taking into account individual parameters, some of which belong to raw materials, and some - directly to production.

Download demo version

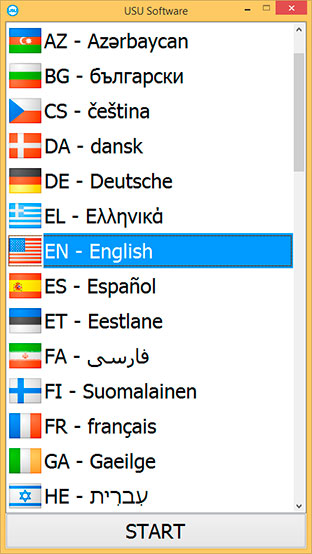

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

The organization of control includes not only production stocks, but also other resources that are involved in the production of products, including food. These are both production technologies and equipment, whose condition is an important factor affecting products, especially food, since containers used in food production must be absolutely clean, i.e. processed appropriately. The state of the means of production must comply with the requirements specified in the technological documentation, any identified deviations must be studied for reasons that allowed such a discrepancy with the initially set standards.

The result of the organization of production control is the identification of defective products, in the case of food products - spoiled during the preparation process. The control department also includes the organization of labor resources, their qualifications, professional skills, on the level of which the quality of manufactured products depends, including food, regardless of how automated production is - making decisions in non-standard situations and maintaining equipment is the responsibility of personnel.

Order an automation of production control

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Automation of production control

The software configuration for organizing control provides convenient forms for registering control operations, which is regularly carried out by the production organization at all stages and participants in production. Electronic reporting forms have personal owners - persons admitted to performing such duties, and the presence of each of their own reporting forms increases their responsibility for the quality of the information they enter into these forms.

External documents can have the form that is approved in the industry for the organization of a certain type of control, and such a reporting document will be considered basic, and can have a form approved by the production organization itself when exercising control that has internal significance. Filling out the forms by users leads to an automatic result, since the methods for evaluating the obtained observations are a function of the software configuration for organizing control, as well as calculation methods for quantifying indicators.

In a word, measurements, observations, samples are the prerogative of personnel, together with timely input into the automated control system, processing and evaluation is the responsibility of the software configuration for organizing control. The final chord of such a duty will be an analysis of the results obtained with the identification of inconsistencies and their causes.

Analytical reporting automatically generated in each period allows you to correct the detected deviations with a parallel study of the factors that caused such deviations. This control method allows you to maintain processes in accordance with the requirements, rules, and standards of production, especially food production, where control measures are carried out with high frequency. Traditional methods do not provide the same measurement accuracy, lag behind in the speed of processing control results and do not have structured reports on control indicators.